| |

DE Busduct @ Powerline Series

|

|

CONDUCTOR

|

|

| With only 99.9% purity copper will be used in our product to ensure low surface contact resistance and low voltage drop. All contact surface was electroplated with tin, this is to prevent surface from oxidation but to improve contact resistance. |

|

|

|

|

|

|

|

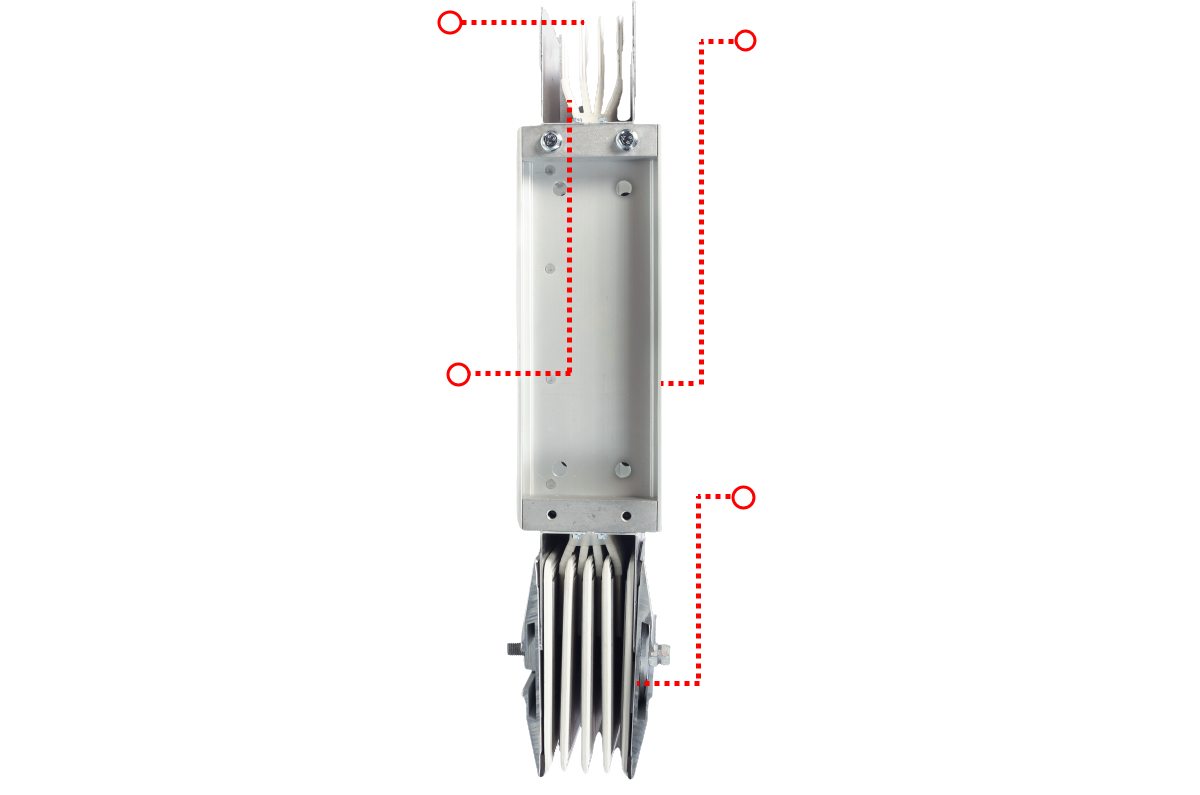

HOUSING

|

| The Extruded Aluminium Housing with finishing of anodising helped it prevent corrosion. |

|

| Aluminium is good in heat dissipation. |

|

| Our patented two piece housing design improved the entire ingress protection of DE Busduct. |

|

All the below test was tested on every rating instead of representative:

- Light weight and passed mechanical impact test

- Highest IK10 standard

- Lifting test & ability to withstand mechanical loads test passed with heavy load

|

|

Type of housing available upon request:

- Electro Galvanised Steel

- Stainless Steel

|

|

|

|

|

|

|

INSULATION MATERIAL

|

| Insulation used in DE Busduct, Powerline system is manufactured with a Class B rated (130°C) polyester film. The insulation wraps around each bus bar, giving excellent separation from phase-to phase and phase-to-ground while enhancing the short circuit rating and long lasting. |

| |

Optional:

Polyester film

Class F (155°C)

Class H (180°C)

Electrostatic Powder Coating |

| |

|

|

|

|

|

|

|

JOINT STACK

|

| The design of joint for DE Busduct is Bridge Type. Tin plated the contact surface for stable e�ciency. Easy & faster installation.Design compliance with clearance & creepage distance standard. Double headed bolt is used on the joint with 55lb/ft +-5 designed for easy usage. Allow 10mm adjustment to correct site measurement inaccuracy. |

|

|

|

| |

|

DE Busduct @ Powerline Series

|

| Technically, a busduct system comprises layers of rigid and flat copper bars arranged in parallel, sheathed in an inorganic synthetic insulator. At the terminals, the conductor bars flare out to form a connection point where they can be joined to a range of busduct components to form extensions or connected to a switchboard to split the transmission. |

|

| The POWERLINE Series is Dynamic Electrical’s main product lineup, comprising an array of busduct components and auxiliary systems to meet the exact requirements of our clients to move electrical energy through the power supply, transformer, switchboard, and main power distribution network. |

|

| POWERLINE busducts are rated for 400A to 6300A, and their versatility has led to its use in a range of industrial applications, including commercial, industrial, high-rise structures, power plants, and high-tech environments. |

|

|

|

| |

Advantages of POWERLINE Busduct Systems

|

Excellent Electrical Properties

|

|

| Made from high-conductivity copper or aluminium, DE Busduct Systems boasts high electrical conductivity that significantly reduces electrical impedance, resulting in improved power output efficiency and minimised power loss. |

|

| |

EZ Joint

|

|

| The modular design of Mono block bridge type joint makes installation easier, thereby reducing the manpower and time required for installation. |

|

| |

UL Product IQ

|

|

| POWERLINE series is tested and certified in accordance to standards and continuity surveillance by the UL PRODUCT IQ to ensure the quality of each product is always consistent with the quality of the samples sent for testing. |

|

| |

Double Insulation for Enhanced Protection

|

|

| POWERLINE is double insulated with epoxy and Mylar, both complementing each other to overcome the limitation of each insulation properties, making POWERLINE series conducive to be used under various challenging conditions. |

|

| |

Green Energy Saving

|

|

| The products are made to meet the green building standards. The POWERLINE series is created as an environmental friendly product that contributes towards a green future for all. |

|

| |

Exceptional Housing Design

|

|

| Incorporating our patented two-piece and boltless housing design, POWERLINE uses SPR (Self-Pierce Riveting Technology) to connect the two-piece housings to enhancing the continuity of grounding and mechanical strength. This also reduces the gaps during assembly and lowers the safety hazards of water intrusion. In addition, the system’s aluminium housing is light-weight and is anodised to increase corrosion resistance. Effectively, it helps to increase its long-term reliability for transmission of high-voltage electricity flow. |

|

|

| |

| |

Comparison of Busduct System with Cabling System

|

| Characteristic |

Busduct System |

Cable System |

| Configuration |

Linear, with outgoing outlets (via power junctions) arranged in serially |

Cables are often connected to a single feed-in point, resulting in a dense accumulation of cables |

| Safety |

Complies with IEC 61439-6 |

Based on type and quality of design |

| Flexibility |

Highly modular, with power-junctions retrofittable to create new power outlets; live assembly possible |

Requires cable splicing, clamping points, sleeves, or parallel lines to create new power outlets or to modify the system post-installation; requires de-energised state for assembly work |

| Fire Safety |

Low availability of combustible material; high short-circuit tolerance |

PVC and PE cables are 10 and 30 times higher than busduct systems in fire load (strength of fire in event of combustion) respectively |

| Electromagnetic Shielding |

Aluminium housing |

Usually none; dependent on type of bundling with single-conductor cables |

| Current Load Capacity |

High |

Depends on type of installation, accumulation, and operating conditions |

| Presence of Halogen/ PVC |

None |

Present in standard cables; halogen-free cables prohibitively expensive in many circumstances |

| Space and Size |

Compact relative to current load capacity |

Large due to bending radii, type of cable, installation, and current load |

| Installation Complexity |

Modular assembly simplifies installation |

Requires tedious cable preparation leading to substantially slower installation |

|

|

|

|